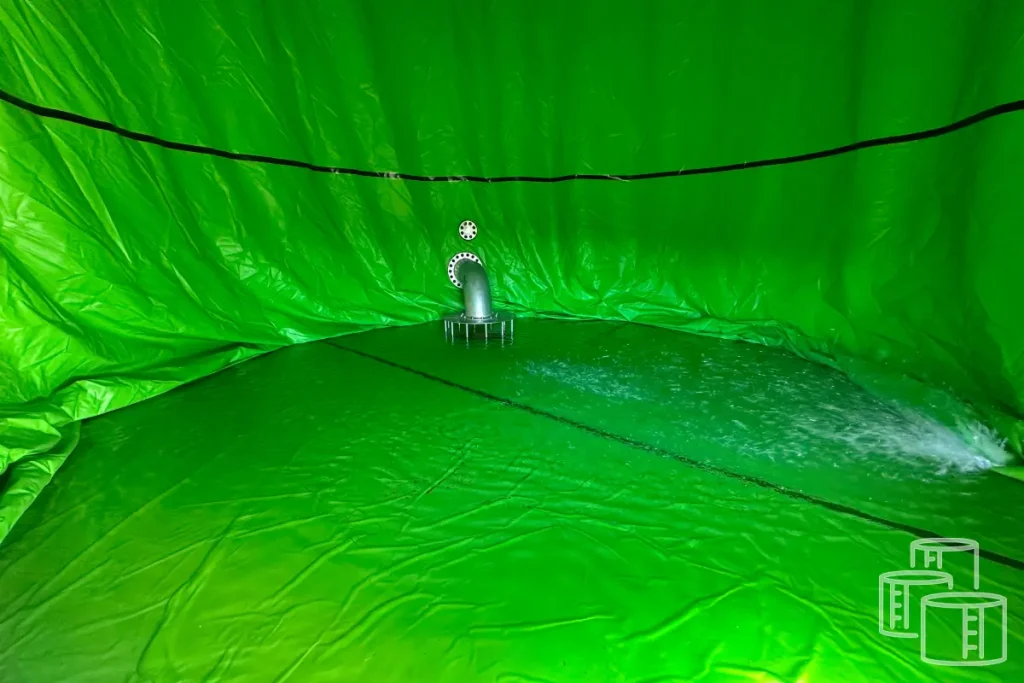

Secondary containment tank liners are designed to prevent leaks and spills from contaminating soil and groundwater. They act as a protective barrier inside or beneath tanks, bunds, and spill containment systems. Businesses in industries such as mining, agriculture, and chemical processing rely on secondary containment liners to stay compliant with environmental regulations while ensuring long-term storage safety.

These liners are commonly made from high-strength geomembranes, HDPE, or reinforced PVC materials. Their flexibility, chemical resistance, and durability make them ideal for secondary containment systems in both commercial and industrial settings.

Tank Liners for Leak Prevention and Long-Term Durability

Tank liners provide an internal protective layer that prevents corrosion, leakage, and contamination in water tanks, chemical tanks, and concrete storage structures. Without a liner, tanks are exposed to cracks, rust, or chemical damage that can compromise stored liquids.

Modern water tank liners and industrial tank liners are engineered for potable water, wastewater, and chemical applications. Depending on the requirements, options include polyethylene liners, PVC liners, and reinforced flexible membranes. These solutions extend tank life, reduce repair costs, and ensure water quality.

Commercial Tank Liners: Built for Heavy-Duty Applications

For businesses, commercial tank liners are a cost-effective way to protect large-scale storage facilities. Whether it’s a municipal water supply, agricultural irrigation tank, or industrial chemical storage, commercial liners guarantee safe, leak-free operation.

Key advantages of commercial water tank liners include:

- Protection against corrosion and chemical attack.

- Easy installation without replacing the entire tank.

- Compatibility with concrete, steel, and fiberglass tanks.

- Long lifespan with minimal maintenance.

These liners are suitable for both domestic and commercial tank servicing, ensuring compliance with safety and environmental standards.

Choosing the Right Liner for Your Application

When selecting between tank liners and secondary containment liners, factors such as stored liquid type, tank size, and regulatory requirements must be considered.

For example:

- Potable water liners must be certified safe for drinking water.

- Chemical-resistant liners are needed for industrial applications.

- Secondary containment systems require heavy-duty geomembranes for spill prevention.

Working with professional installers ensures that the right material, thickness, and fitting method are chosen for long-lasting protection.

Conclusion

Investing in secondary containment liners, tank liners, or commercial tank liners is a proactive step toward safety, compliance, and cost savings. From preventing leaks to extending tank lifespan, these solutions protect both your assets and the environment.

Extend the life of your tanks—get expert advice on the best liner and containment options for your facility. Contact us today at 1800 337 795.